Innofab45Store

Epitum JL Industrial Dual Head FDM 3D Printer

Epitum JL Industrial Dual Head FDM 3D Printer

Couldn't load pickup availability

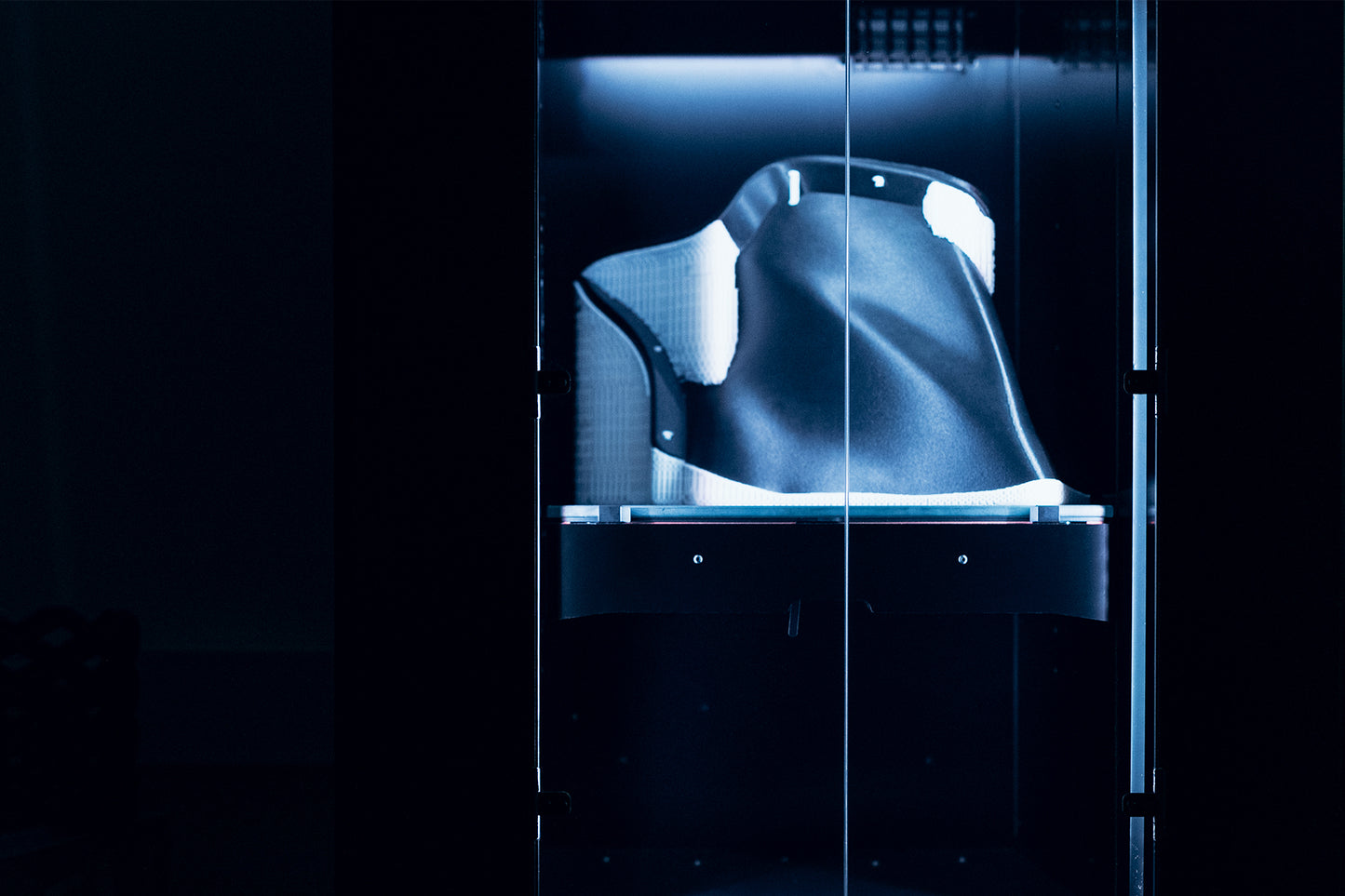

A studio of its own in a single unit

The perfect combination of double-nozzle printing and large-size models. The high degree of defect tracking on large parts and pad flatness during printing gives the most controlled result. The best solution for high-volume production.

What Can Epitum Do and Other Hobbyist, DYI 3D Printers Can't?

3D Printing Advanced, High-temp Engineering Materials Made Possible

-

PA-6, PC, PPSU, VXL111 and PEEK, are high temperature "super polymers", these materials and others are notoriously difficult to print on hobbyist 3D printers, if not impossible.

Epitum's hardware makes printing such material as easy as printing PLA, with ready-to-go profiles for a variety of materials!Active chamber heating up to 90c

Most closed printers nowadays boast "heated chambers", and technically, in most cases, they are heated chambers, however, the chamber would use the build plate temperature to generate and trap heat within the chamber, normally up to 60c.

Epitum's heated chamber uses real heaters to get the chamber temp of up to 90c, this helps to create stronger models thanks to better sintering of the layers, with our 3D Printers, the printed parts are less anisotropic and stronger in the layer direction, with no warping or delamination.Smart Systems for Less Fails, Less Waste, and More Safety

Filament Flow Control*, End-of-Filament Sensor, First Layer Control, Built-in Profile System, Network Printing, Filament drying mode, Printer status notification system, Auto-control workability of all systems, Surface print control system and many more features give an improved user experience, higher likelihood of print success, and more safety.

Filament Flow Control: This is NOT your average filament sensor, the device that's triggered physically by the filament and fails to aid when the filament snaps before the trigger, or when you have a clog. a Filament Flow Control lives near the nozzle and detects the slightest lack of flow to pause the print, saving precious material, and time.

Dual Heads for Dual Material Printing, But....

Filament changers are not breaking news, plenty of 3D Printers would come with separate modules to swap between filaments, however, they often fail with flexible material, and mostly the printers with such systems will rely on a single printhead, which requires purging upon swapping filaments, wasting time and material.

Epitum JL is equipped with a patented tool changer that switches in an instance between the dual hotends, JetSmart System - 2 nozzles at 1 extruder, no need for purge and wait.

Hardware Excellence, and Software Uniqueness, EasySupports to the rescue

In 3D Printing, hardware and software work in parallel, hence, we are constantly working on our Printoforma slicer to improve UX and increase options, and one of those options is our "EasySupports" feature, which breaks the supports vertically into segments separated by the expensive support material, instead of printing the supports entirely with the support material.

Selling Solutions, Not Machines...

With our industrial grade 3D printers, you will enjoy a

- 24/7 technical support from industry experts

- Shipping and on-site installation

- Professional training

- Top notch after-sales maintenance and service

We want you to make use of the machine, help you choose right, print right, and use the 3D printer for your project or product as intended, we are not a machine seller, we are a solution seller.

Not a Technical Point, but Made in UAE...

We are proud and honored to be manufacturing Epitum 3D Printers in the United Arab Emirates. At our 3D Printing factory in Jebal Ali Industrial, we are always working on improving our machines and services, and we are delighted to be close to our clients across the UAE and GCC to provide the naseberry aid and support when needed.

Specifications

| Category | Specification |

|---|---|

| Printing technology | Fused Filament Fabrication (FFF) |

| Nozzle switching technology | JetSmart (2 nozzles at 1 extruder), HotSwap |

| Build volume | 360 × 360 × 610 mm |

| Extruder max printing temperature | 430 °C (806 °F) |

| Heated bed max temperature | 150 °C (302 °F) |

| Print speed | Up to 500 mm/s |

| Layer resolution | 10 microns (0.01 mm) |

| Build rate | Up to 130 cm³/h |

| Positioning resolutions | 11 × 11 × 1.25 microns |

| Filament diameter | 1.75 ± 0.1 mm |

| Nozzle diameter | 0.5 mm (toolkit 0.2–1 mm) |

| Active chamber max heating | Up to 90 °C |

Mechanics

| Category | Specification |

|---|---|

| Casing | Aluminium composite |

| Frame | Steel, 3 mm |

| Heated bed construction | Aluminium, glass |

| Guides | XY cylindrical (steel), Z cylindrical (steel) |

Electricity

| Category | Specification |

|---|---|

| Networking | 220 ± 15%, 50 Hz (option 110 ± 15%, 60 Hz) |

| Maximum power consumption | 2.2 kW |

| Interfaces | Wi-Fi, Ethernet, USB 2.0 (flash drive in toolkit) |

Printing Materials

| Category | Supported Materials |

|---|---|

| Materials | ABS, PLA, ASA, HIPS, PVA, TPU, PP, PETG, PA (6/12/66), ABS (GF/CF), PC, PEEK, PEKK, PPSU, SBS, PPS, WAX, and composites with CF and GF |

Physical Characteristics

| Category | Specification |

|---|---|

| Printer dimensions | 650 × 605 × 1000 mm |

| Weight | 75 kg |

Software

| Category | Specification |

|---|---|

| Software | Printformer |

| File types | *.stl, *.amf, *.obj, *.3ds, *.etpf |

Features

| Category | Feature List |

|---|---|

| Primary systems | Filament Flow Control, End-of-Filament Sensor, First Layer Control, Built-in Profile System, Network Printing |

| Additional features | Filament drying mode, Printer status notification system, Auto-control workability of all systems, Surface print control system |

| Build plate leveling | Automatic leveling |

Share